Masin pembuat pelet pakan ayam

| Brand | Taizy |

| Modell | KL-120, KL-150, KL-210, KL-260, KL-300 |

| Výkon | 3-22kw |

| Uzito wa mashine | 100-450kg |

| Uwezo | 120-1200kg/h |

| Urefu wa pellet ya chakula | 2-10cm |

Sasa unaweza kuuliza wasimamizi wetu wa miradi kwa maelezo ya kiufundi

Mashine ya pellet ya chakula cha kuku inashughulikia malighafi mbalimbali, kama unga wa mahindi, unga wa majani, na bran ya ngano, na kugeuza kuwa pellet za chakula cha kuku. Pellet kawaida ni urefu wa 2-10cm na zinaweza kubadilishwa.

Mashine ya pellet ya chakula cha kuku ya Taizy ni yenye ufanisi mkubwa, ikiwa na uwezo wa uzalishaji wa kilo 120-1200 kwa saa. Inafaa kwa uzalishaji wa saizi zote. Ikiwa wewe ni mkulima binafsi au kiwanda cha usindikaji wa chakula, mashine zetu zinaweza kukidhi mahitaji yako.

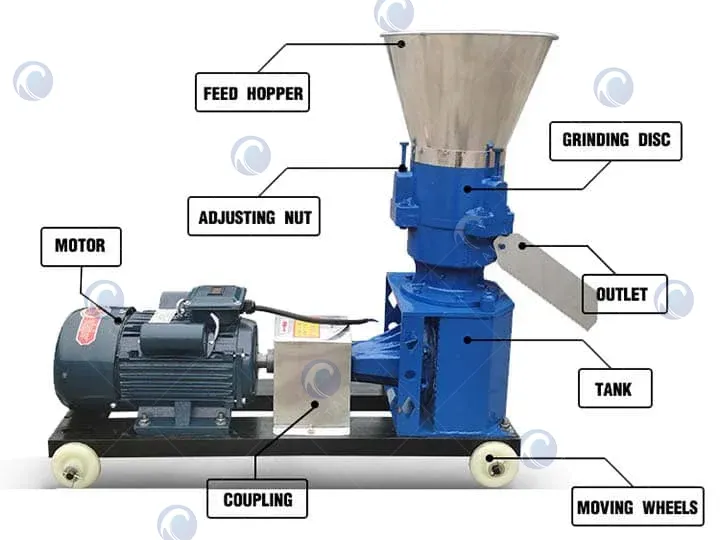

Vipengele vya mashine ya pellet ya chakula cha kuku

- Mashine yetu ya kutengeneza pellet za chakula cha kuku ni : rahisi kutumia : na haihitaji mafunzo maalum. Kwa kawaida, mtu mmoja anaweza kuendesha.

- Mashine ya kutengeneza pellet za chakula cha kuku ya Taizy ina uwezo wa uzalishaji wa 120-1200kg/h na inafaa kwa uzalishaji wa ukubwa wote.

- Pelleti za chakula cha kuku zilizochakatwa na mashine hii ni zina umbo sawa na si rahisi kuvunjika.

- Aina ya matumizi ya vifaa vyetu vya kusindika chakula cha kuku ni pana sana. Haiwezi tu kutumika kusindika chakula cha kuku, bali pia inaweza kutumika kusindika aina mbalimbali chakula kama ng'ombe, kondoo, na farasi.

- : Mashine hii inaweza kuendeshwa na : injini ya dizeli, injini ya petroli, au motor ya umeme: Inafaa kwa matumizi katika maeneo mbalimbali.

- Yake Sehemu za kubadilisha ni rahisi kufunga, na rollers na mold ni nafuu kwa bei.

Muundo wa kiwanda cha pellet ya chakula cha kuku

Muundo wa mashine yetu ya pellet ya chakula cha kuku ni rahisi sana. Inajumuisha hopper ya chakula, ncha ya kurekebisha, diski ya kusaga, gurudumu la kuhamisha, n.k.

Vigezo vya mashine ya kutengeneza pellet ya chakula cha kuku

| Modell | Výkon | Uzito wa mashine | Saizi ya mashine | Uwezo |

| KL-120 | 3kw | 100kg | 0.75*0.32*0.61m | 120kg/h |

| KL-150 | 3kw | 190kg | 0.75*0.35*0.65m | 150kg/h |

| KL-210 | 7.5kw | 230kg | 1.0*0.45*0.96m | 400kg/h |

| KL-260 | 15kw | 360kg | 1.46*0.46*1.15m | 800kg/h |

| KL-300 | 22kw | 450kg | 1.06*0.57*1.15m | 1000-1200kg/h |

Kanuni ya kazi ya mashine ya pellet ya chakula cha kuku

- Maandalizi ya kabla ya kuanzisha: Kwanza, ongeza mafuta ya gia kwenye usafirishaji, rekebisha mvuto wa mnyororo, na endesha mashine bila mzigo ili kuthibitisha uendeshaji wa kawaida kabla ya kuandaa chakula.

- : Lubrication ya die na upimaji wa mashine: Kabla ya matumizi ya kwanza, tumia unga wa majani ya majani yaliyochanganywa na kiasi kidogo cha mafuta ya mboga kama mafuta ya kupaka. Wakati wa kuanzisha mashine, ongeza taratibu malighafi ili kuilinda kwa kina shimo la die hadi chembe zitoke kwa urahisi.

- Uzalishaji rasmi: Baada ya uingizaji mafuta kukamilika, uzalishaji unaweza kuanza kawaida. Urefu wa chembe za chakula unaweza kurekebishwa kwa kubadilisha diski ya kusaga.

- : Kuzima na kusafisha: Baada ya kumaliza usindikaji, fungua screws za kurekebisha ili kuachilia rollers. Baada ya kuzima, safisha hopper na tray ya die ili kuzuia kuziba au kuharibu mashine.

Malighafi na bidhaa zilizokamilika

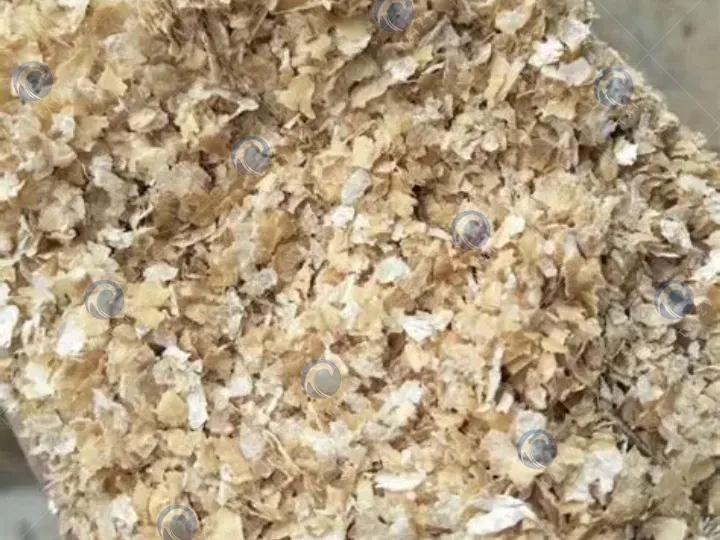

Malighafi: Mashine hii ya kutengeneza pellet ya chakula cha kuku inaweza kutumia malighafi mbalimbali, kama mahindi, maganda ya mchele, shina za pamba, maganda ya mbegu za pamba, bran ya ngano, na unga wa nafaka mbalimbali.

Bidhaa Iliyokamilika: Bidhaa iliyoshinikizwa na mashine ya pellet ya chakula cha kuku ni pellet ya mduara ya 2-10mm, yenye muonekano mzuri, muundo thabiti, na lishe iliyosawazishwa. Ni moja ya aina maarufu za chakula cha kuku sokoni.

Manufaa ya pellet za chakula cha kuku

Ikilinganishwa na chakula cha unga wa jadi, chakula cha pellet kinachozalishwa na mashine ya pellet ya chakula cha kuku kinatoa faida kubwa:

- Kula zaidi kwa chakula: Pellet ni tamu, na kufanya iwe tamu zaidi kwa kuku.

- Kupunguza taka: Pellet ni kidogo zaidi kupigwa na upepo au kuchukuliwa na ndege, na kusababisha matumizi makubwa ya chakula.

- Kuboresha mmeng'enyo na ulaji: Kusukuma kwa joto la juu kunaboresha muundo wa malighafi, na kufanya virutubisho kupatikana kwa urahisi zaidi.

- Kuweka na kusafisha: Joto kali wakati wa mchakato wa kusukuma huua bakteria wengi hatari.

- : Rahisi kuhifadhi na kusafirisha: Pellet ni sugu kwa ukungu, shinikizo, na unyevu, na kuongeza muda wa kuhifadhiwa.

Bei ya mashine ya pellet ya chakula cha kuku

Bei ya mashine ya kutengeneza pellet ya chakula cha kuku inatofautiana kulingana na mambo kama mfano, uzalishaji, aina ya nguvu, malighafi, na usanidi. Kwa ujumla, uzalishaji mkubwa, usanidi wa juu, na malighafi bora ya mold yataongeza bei.

Wakati wa kununua, wanunuzi hawapaswi kuzingatia bei pekee bali pia utulivu wa mashine, uimara, na ubora wa uzalishaji wa pellet. Mashine bora inaweza kudumu kwa muda mrefu, kupunguza gharama za matengenezo, kuhakikisha ubora wa chakula cha kuaminika, na hatimaye kuleta faida zaidi.

Kesi ya Mafanikio ya Mashine ya Pellet ya Kuku Taizy

Mashine nne za kutengeneza pellet za chakula cha kuku zilitumwa Morocco

Hivi karibuni, Taizy ilizalisha kwa mafanikio mashine nne za pellet za chakula cha kuku Morocco. Vifaa hivi vilikuwa sehemu ya zabuni ya vifaa vya mifugo vya eneo hilo. Baada ya kushinda zabuni, mteja alilinganisha chaguzi kadhaa na hatimaye akachagua Taizy.

Tuliwapa mfano unaofaa kulingana na mahitaji ya uzalishaji wa mteja na viwango vya voltage. Vifaa vilisafirishwa kwa mafanikio na kuanza kufanya kazi. Mashine zinafanya kazi kwa utulivu, na mteja anaridhika sana na utendaji wao.

Wasiliana nasi sasa!

Kama muuzaji mwenye uzoefu wa mashine za pellet za chakula cha wanyama, Taizy inajitahidi kuwapa wateja wetu mashine za ubora wa juu na huduma kamili baada ya mauzo.

Mbali na mashine ya pellet ya chakula cha kuku, pia tunatoamashine za pellet za samaki,mashine za pellet za wanyama wa kipenzi, na zaidi. Ikiwa una maswali yoyote, tafadhali wasiliana nasi, tutakupatia suluhisho lako la kubinafsisha.