Animal Feed Pellet Making Machine for pourlty

| Brand | Taizy |

| Model | KL-120, KL-150, KL-210, KL-260, KL-300 |

| Weight | 100-450kg |

| Capacity | 120-1200kg/h |

| Raw materials | Cotton stalks, alfalfa, rice bran, bean cake, etc. |

| Application | Pigs, chickens, ducks, cows, etc. |

You can now ask our project managers for technical details

The animal feed pellet making machine is mainly used to process food pellets for chickens, ducks, cows, and other animals. The pellet size is uniform, and the surface is smooth. The diameter of pellets can be divided into: φ2, φ2.5, φ3, φ3.5, φ4, φ5, φ6, φ7, φ8 and so on. It has a high processing efficiency with a processing capacity of 120-1200kg/h.

Feed pellet mill is mainly suitable for rural farming, pig farms, and other families and small farms. There are many kinds of raw materials available, such as sawdust, rice husk, cotton stalks, cottonseed hulls, wheat bran, all kinds of cereal flour, and so on.

Models of feed pellet mills and their parameters

Animal feed pellet making machines come in different models with different production capacities to meet different needs. Among them, KL-150 and KL-210 are hot-selling models, which are very popular among customers. These two models meet the needs of most production scales.

| Model | Power | Weight | Size | Capacity |

| KL-120 | 3kw | 100kg | 0.75*0.32*0.61m | 120kg/h |

| KL-150 | 3kw | 190kg | 0.75*0.35*0.65m | 150kg/h |

| KL-210 | 7.5kw | 230kg | 1.0*0.45*0.96m | 400kg/h |

| KL-260 | 15kw | 360kg | 1.46*0.46*1.15m | 800kg/h |

| KL-300 | 22kw | 450kg | 1.06*0.57*1.15m | 1000-1200kg/h |

Raw materials and applications of the food pellet maker machine

Raw materials for animal feed pellet making machine: various grain flour, alfalfa, corn stalks, rice bran, cottonseed hulls, wheat bran, and so on.

Application of food pellet milling machine: it can process the raw materials into various animal feeds such as chicken, duck, cow, pig, etc.

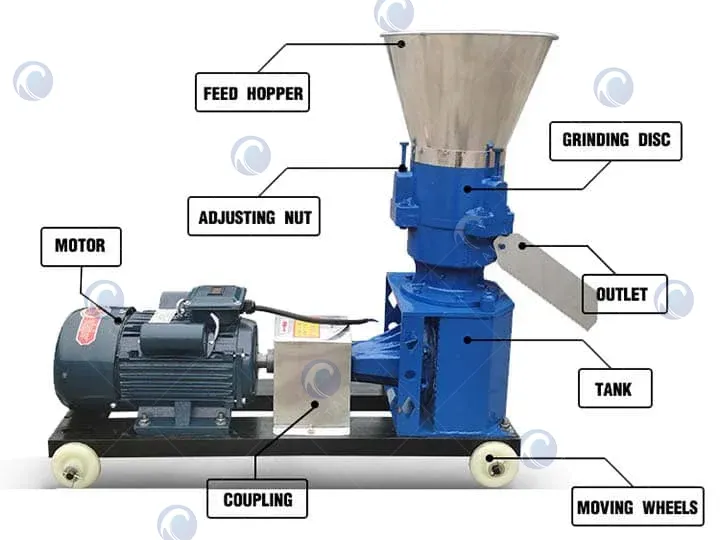

Construction of the flat die pellet mill

It is mainly composed of a feeding hopper, an adjusting nut, a motor, a moving wheel, and so on. The feed pellet machine is well-designed; not only is the production efficiency very good, but the operation is also very simple. It can help you save a lot of time and energy!

This animal feed pellet making machine can be equipped with a diesel engine, petrol engine, pto, and electric motor. It is suitable for all kinds of areas and is not limited by power supply.

Accessories of the feed pellet maker machine

The main accessories of the animal feed pellet making machine are the grinding disc and the pressure roller.

The grinding disc is mainly used to determine the diameter of the food particles. The diameter of the finished pellets can be divided into: φ2, φ2.5, φ3, φ3.5, φ4, φ5, φ6, φ7, φ8, and so on. You can change the grinding plate according to your needs.

Advantages of Taiy animal feed pellet making machine

- Simple operation: the operation is simple and can be done by only one person, and no professional technician is needed.

- High production efficiency: it has a production capacity of 120kg-200kg/h, which can meet the needs of different scales of production.

- Wide range of applications: most feed materials, such as corn grain, straw, stalks, rice, wheat, and wood chips, are suitable for our pellet mill.

- Available with four power sources: we have designed our pellet mill models with petrol engine, diesel engine,electric motor, and pto power output.

- Low maintenance cost: it has easy replacement of spare parts and low cost of rolls and moulds.

- Price advantage: we are self-produced and have a price advantage in the same market.

- After-sales guarantee: Taizy feed pelletizer has a strong after-sales team and professional technical support to solve your problems in time.

About the price of the animal feed pellet machine

The price of a feed pellet mill can be affected by a number of factors. Two of the main influencing factors are shown as follows:

Different price for different models: the price of the feed pellet maker machine will be different for different models. Generally speaking, the price is higher for models with larger capacity. For example, the price of KL-210 is higher than that of KL-150.

Different prices for different accessories: on the one hand, the number of accessories will affect the price. The price will be higher if there is more demand for accessories. On the other hand, customised accessories will be more expensive.

Production lines for the feed pelletizer machine

In order to meet the needs of different customers, we also offer the production line for animal feed pellet making machine. These include hammer mill, screw conveyor, mixer, feed pellet making machine, cooling machine, weighing and packing machine, and so on.

The production line can greatly save manpower and improve production efficiency. Let you realise one-stop processing. Whether you want to start a poultry pellet production business or continue to expand your production, this production line is a great choice!

The successful case of the Taizy pellet feed mill machine

In April, a customer in the Democratic Republic of Congo ordered a KL-210 animal feed pellet making machine. Through the communication, we learned that this customer has a farm. He needs an animal food pellet machine with a capacity of 300-400kg/h. And hope to receive the machine within 15 days.

Based on the customer’s needs. We recommend this feed pellet making machine mill to the customer. In order to enable the customer can receive the goods as soon as possible, we worked overtime overnight to produce. Ten days later, we finished the production and sent the product photos to the customer. The customer was very satisfied and paid the final payment.

After he received the feed pelleting machine, he said he was very satisfied and hoped to have more cooperation in the future! If you need a flat die pellet mill, please contact us immediately. We will provide you with the most professional service and equipment!