Animal Feed Pellet Production Line

In the dynamic realm of modern agriculture, where precision and efficiency are paramount, the Animal Feed Pellet Production Line emerges as a cornerstone of sustainable livestock management. This sophisticated system represents the convergence of cutting-edge technology and agricultural expertise, aimed at revolutionizing the way we nourish our livestock.

Designed to cater to a diverse range of animal species, from poultry and livestock to aquaculture, the Animal Feed Pellet Production Line transforms raw ingredients into nutritionally balanced pellets. Its intricately engineered processes ensure optimal nutrient density, promoting healthy growth, improving feed conversion rates, and ultimately, enhancing the overall well-being of the animals.

What is the animal feed pellet production line?

The Animal Feed Pellet Production Line is a mechanized system designed for the efficient and automated production of animal feed pellets. It’s a comprehensive setup that encompasses various stages involved in the transformation of raw materials into nutritionally balanced and easily digestible pellets suitable for consumption by a wide range of livestock and poultry.

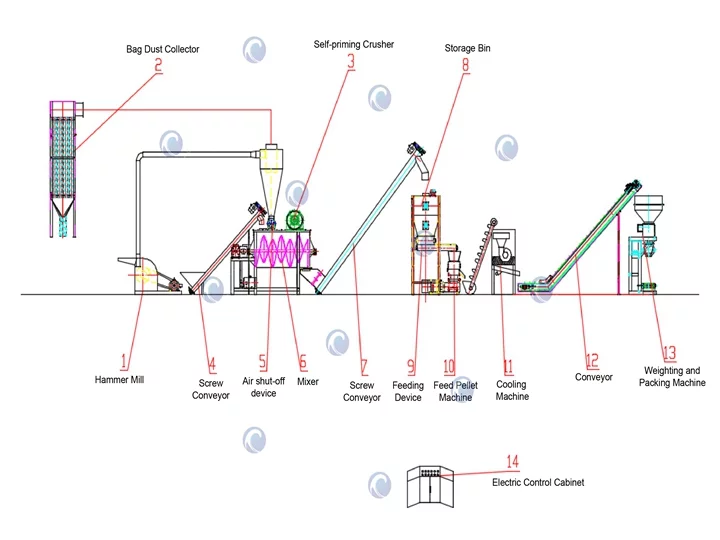

Main components of the feed pellet production line

1. Hammer Mill

- Function: It crushes raw materials to a suitable size for further processing, such as breaking grains and soybean meal into smaller particles.

- Working Principle: It uses mechanical force to grind and crush the raw materials to achieve the desired particle size.

| Capacity | Size | Weight | Power |

| 600-1300kg/h | 1850*1060*1240mm | 850kg | 22kw |

2. Bag Dust Collector

- Function: It removes dust and impurities to maintain a clean production environment, ensuring worker health.

- Working Principle: It uses filter bags to trap particles from the airflow, keeping the air in the environment clean.

3. Self-priming Crusher

- Function: It further refines the raw materials to ensure uniformity and consistency of the pellets, enhancing their quality.

- Working Principle: It uses mechanical force and a suction mechanism to crush the raw materials while simultaneously extracting dust.

4. Screw Conveyor

- Function: It transports the processed raw materials into the production line, enabling automated material feeding.

- Working Principle: It uses mechanical devices to lift and convey the raw materials through a conveyor pipe to the next processing unit.

| Capacity | Power | Size | Weight |

| 0-1000kg | 1.5kw | 2800*850*740mm | 200kg |

5. Air shut-off device

- Function: It adjusts the generated airflow to ensure the material flows smoothly within the crusher and to control the particle size.

- Working Principle: It regulates the airflow speed and direction by controlling the fan’s airflow.

6. Mixer

- Function: It blends different types of raw materials uniformly to ensure a balanced nutritional profile in the feed pellets, improving feed quality.

- Working Principle: It uses mechanical mixing devices to thoroughly blend different types of raw materials.

| Capacity | Size | Power | Weight |

| 0.5-1.2T | 2100*800*1550mm | 4kw | 210kg |

7. Screw Conveyor

Function: It feeds the mixed feed into the storage bin, enabling automated material feeding.

8. Storage Bin

- Function: It stores the mixed feed to ensure continuous operation of the production line.

- Features: It typically has a certain capacity to meet the production needs for a specific time period.

9. Feeding Device

Function: It transports the mixed feed powder to the pellet mill for pelletization.

10. Feed Pellet Machine

- Function: It compresses the mixed feed through a die to form compacted pellets, improving texture and storability.

- Working Principle: It uses a die and heat treatment to shape the mixed material into pellets.

| Capacity | Size | Power | Weight |

| 80-120kg/h | 800*350*670mm | 4kw | 95/110kg |

11. Cooling Machine

- Function: It removes excess moisture from the freshly extruded pellets, achieving the desired moisture content for improved stability and storage.

- Working Principle: It uses hot air to evaporate moisture from the pellets, reducing humidity.

| Capacity | Size | Power | Weight |

| 0-500kg/h | 1800*750*1100mm | 0.75+2.2kw | 220+65kg |

12. Bucket Conveyor

Function: It transports pellets to the next processing stage or directly to the packaging machine, enabling automated pellet transportation.

| Capacity | Power | Size | Weight |

| 0-2000kg | 2.2kw | 5600*600*1500mm | 300kg |

13. Weighting and Packing Machine

Function: It packages the finished pellets for storage and transportation, maintaining product quality and hygiene.

| Power | Size | Weight |

| 1kw | 1200*1200*2400mm | 600kg |

Why choose to buy the animal feed pellet production line

Choosing to invest in an Animal Feed Pellet Production Line can bring a multitude of benefits for businesses involved in animal husbandry and agriculture.

- Improved Feed Quality: A dedicated production line ensures consistent and high-quality feed pellets. This can lead to healthier and more productive livestock, resulting in improved growth rates, higher milk or egg production, and better overall performance.

- Customization and Flexibility: A well-designed production line allows for customization of feed formulations. This flexibility enables farmers to tailor feed to meet the specific nutritional requirements of their animals, which is crucial for optimal growth and performance.

- Cost-Effectiveness: Producing feed in-house can often be more cost-effective in the long run compared to purchasing pre-made feed. It reduces dependency on external suppliers and allows for bulk purchasing of raw materials, potentially lowering overall costs.

- Reduced Feed Waste: By producing feed on-site, you can control the quantity and quality of feed produced, minimizing waste. This can lead to cost savings and a more sustainable operation.

- Hygiene and Safety Standards: A dedicated production line adheres to strict hygiene and safety standards, ensuring that the feed is free from contaminants or impurities that could adversely affect animal health.

- Traceability and Quality Control: With your own production line, you have complete control over the sourcing and quality of raw materials. This allows for better traceability and quality control throughout the production process.

- Adaptability to Specific Animal Needs: Different species and life stages of animals have specific dietary requirements. A dedicated production line allows for easy adjustment of formulations to cater to different animal species and their unique nutritional needs.

- Minimized Dependency on External Suppliers: Owning a production line reduces reliance on external suppliers for feed. This can be particularly advantageous during times of supply chain disruptions or fluctuations in feed prices.

- Market Opportunities: With the ability to produce feed, there may be opportunities to enter the feed production market, supplying neighboring farms or businesses. This can diversify revenue streams and create additional income.

Ultimately, investing in an Animal Feed Pellet Production Line empowers farmers with greater control, flexibility, and quality assurance in their feed production process, leading to healthier and more productive livestock operations. It can also contribute to cost savings and potential business expansion opportunities.

FAQ about the feed pellet production line

What types of animals can benefit from feed pellets produced by this line?

The feed pellets produced by this line are suitable for a wide range of animals, including poultry (such as chickens, ducks, and turkeys), livestock (such as cattle, pigs, and sheep), as well as fish in aquaculture.

How does the production line ensure feed quality?

The production line employs precise processes and quality control measures at each stage. This ensures that the feed pellets meet nutritional requirements and are free from contaminants.

Can the production line handle different types of raw materials?

Yes, the production line is designed to handle a variety of raw materials, including grains, protein sources (such as soybean meal), vitamins, minerals, and additives. It can be adjusted to accommodate different formulations.

Can this production line be used for small-scale farming operations?

Yes, the production line can be adapted for small-scale farms. It offers scalability, allowing farmers to adjust the production capacity to suit their specific needs.

Is training available for operating and maintaining the production line?

Yes, we offer training and support for operators to ensure that they can effectively run and maintain the production line.