How to Choose the Suitable Feed Mill Pellet Machine?

Selecting the right feed mill pellet machine is crucial for ensuring efficient and high-quality feed production.

With numerous options available in the market, it can be overwhelming to make the best choice. Here’s a comprehensive guide to help you navigate through the selection process effectively.

1. Determine Your Production Requirements

Before choosing a feed mill pellet machine, it’s essential to assess your production needs. Consider factors such as the desired output capacity, types of feed to be produced, and the frequency of production.

Understanding your specific requirements will help narrow down the options and ensure you select a machine that can meet your production goals effectively.

2. Evaluate the Pelletizing Mechanism

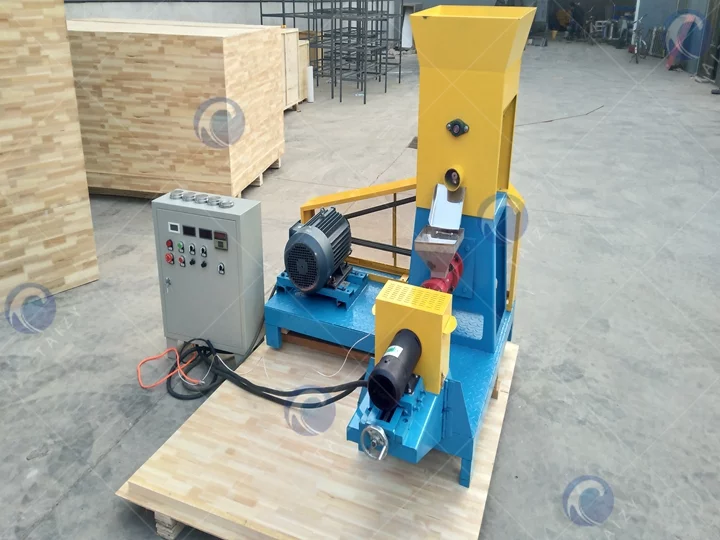

Different feed mill pellet machines utilize various pelletizing mechanisms, including flat die pellet mills and ring die pellet mills.

Flat die pellet mills are suitable for small to medium-scale production and are more cost-effective, while ring die pellet mills are ideal for large-scale production due to their higher efficiency and output capacity.

Evaluate the pros and cons of each mechanism based on your production requirements to determine the most suitable option for your operation.

3. Consider the Power Source

Feed mill pellet machines are available in electric, diesel, and gasoline-powered models.

Electric pellet machines are convenient for indoor use and offer consistent performance, but they require access to electricity.

Diesel and gasoline-powered models are more versatile and suitable for outdoor use or areas with limited access to electricity.

Consider your power source availability and operational requirements when choosing the power source for your pellet machine.

4. Assess the Durability and Maintenance Requirements

Investing in a durable and low-maintenance feed mill pellet machine is essential for long-term reliability and cost-effectiveness.

Evaluate the build quality, materials used, and reputation of the manufacturer to ensure you select a machine that can withstand continuous operation and minimal maintenance requirements.

Additionally, consider factors such as warranty coverage and availability of spare parts to facilitate timely repairs and maintenance.

Taizy Machinery offers robust, high-quality pellet machines designed for longevity and minimal upkeep. With user-friendly maintenance features, our machines ensure smooth operation and minimal downtime, maximizing your productivity effortlessly.

5. Consider Budget and Return on Investment

Finally, consider your budget constraints and the potential return on investment when choosing a feed mill pellet machine.

While it’s essential to select a machine that meets your production requirements, it’s equally important to ensure that it offers long-term value and profitability for your operation.

Compare the upfront costs, operational expenses, and expected productivity gains to determine the most cost-effective option that aligns with your budget and business goals.

Conclusion

In conclusion, choosing the suitable feed mill pellet machine requires careful consideration of your production requirements, pelletizing mechanism, power source, durability, and budget constraints.

By following these guidelines and conducting thorough research, you can select a machine that optimizes efficiency, productivity, and profitability for your feed production operation.