Fish feed pelletizer | Floating fish feed extruder

| Model | DGP80-B |

| Capacity (t/h) | 0.2-0.3 |

| Main power (kW) | 22 |

| Feeding power(kW) | 0.6 |

| Spiral diameter (mm) | φ80 |

| Cutting power(kW) | 0.6 |

| Size(mm) | 1800*1450*1300 |

| Weight(kg) | 695 |

You can now ask our project managers for technical details

Fish feed pelletizer stands as the epitome of precision and efficiency in the production of nutritionally balanced feed for aquatic species. This cutting-edge machine takes center stage in the aquaculture industry, offering a seamless and tailored approach to transforming raw materials into high-quality pellets.

Designed to meet the specific nutritional requirements of various fish species, the Fish feed pelletizer sets a new standard for feed processing, ensuring consistency, quality, and optimal growth in aquaculture operations of all scales.

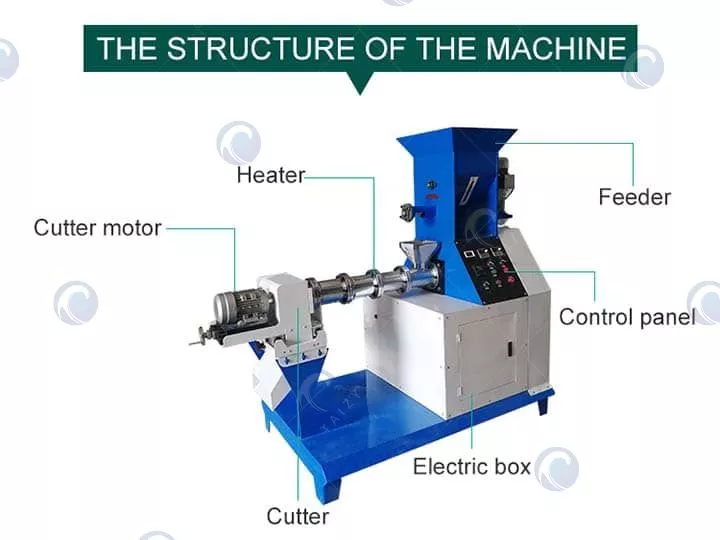

What’s the fish feed pelletizer’s structure?

The fish feed pelletizer mainly contains a hopper, control panel, electric box, heating system, cutting knife motor, cutting knife, etc.

The whole machine is simple, compact, small footprint, and is easy to operate.

Why use the floating fish feed extruder?

- The heat generated by the floating fish feed extruder in the pelleting process can crack the starch in the raw material, making the feed material more digestible.

- The feed processed by a fish feed pelletizer is not easy to stratify, which can reduce the waste of feed. It can also improve the palatability of the feed and shorten the feeding time.

- The fish feed pelletizer can kill some pathogenic bacteria and most of the viruses in the process of puffing and heating thus reducing the level of toxins in the raw materials of fish feed.

- Fish food puffing machines can produce different sizes and shapes of different aquatic feeds.

- The feed produced by the fish food-making machine is not fragile, thus it can reduce the number of fines produced during transportation.

Key advantages of fish feed pellet machine

- Efficient Feed Conversion: The equipment ensures the effective transformation of raw materials into top-quality pellets, maximizing the feed’s nutritional value.

- Customization of Feed Formulations: Users have the flexibility to easily tailor feed formulations to meet the specific nutritional needs of diverse fish species and growth stages, optimizing overall health and development.

- Consistent Pellet Quality: Consistency in pellet size, shape, and density is maintained by the machine, ensuring uniform feed quality and fostering well-balanced nutrition for aquatic species.

- Enhanced Nutrient Retention: Through its extrusion process, the machine safeguards the nutritional integrity of feed ingredients, resulting in increased nutrient retention and enhanced absorption by fish.

- Hygienic and Sterile Production: Pellet production involving high-temperature processing sterilizes the feed, mitigating the risk of diseases and contaminants in aquatic environments.

- Cost-Effectiveness and Productivity: By optimizing the feed production process, the machine contributes to cost-effective and streamlined operations, enhancing productivity for aquaculture ventures of varying scales.

Technical specifications of the fish food pellet mill

| Model | DGP80-B |

| Capacity (t/h) | 0.2-0.3 |

| Main power (kW) | 22 |

| Feeding power(kW) | 0.6 |

| Spiral diameter (mm) | φ80 |

| Cutting power(kW) | 0.6 |

| Size(mm) | 1800*1450*1300 |

| Weight(kg) | 695 |

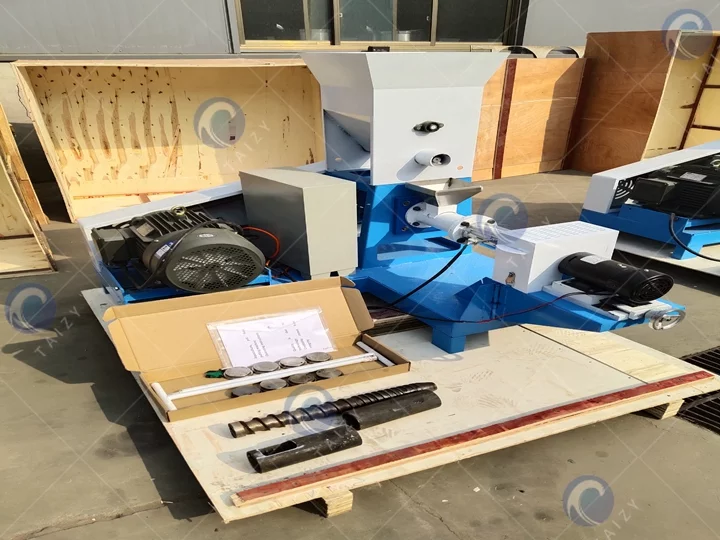

Floating fish feed pellet machine shipped to Ghana

Our customer from Ghana, who is in the fish rearing business, needs a machine to make a floating fish food pellet mill.

He is raising 20,000 fish. He needs 1500-2000 kg of fish feed pelletizer per day. Based on the customer’s needs we recommend the DGP70-B fish feed mill machine. The output of the floating fish feed machine is 0.18-0.20t/h.

The customer is concerned that the machine must be powered by a diesel engine. So our sales manager provided the PI of the diesel engine to the customer, and the customer was satisfied with all aspects and decided to pay. And we will send 6 molds to the customer.

Then we confirmed the port of Tema to the customer. Immediately after making the fish feed pelletizer, we arranged to send the machine to the port of Tema.

How to operate the floating fish feed machine safely?

Safety Warning

When the fish feed pelletizer output material, the puffing machine discharge port in front of the people forbidden to stand.

Protective Wear

Operators should wear high temperature-resistant gloves to prevent burns.

Equipment Preparation

Before starting the fish feed pelletizer should confirm that tools and other items are removed from the puffing machine.

Regular Inspection

In equipment operation, the operator should often inspect the entire unit operation, and abnormalities found in time to adjust.

Safe Shutdown

After the shutdown, disassembly of the discharge box prevents the internal pressure so that the puffed material together with the discharge box is washed out.

FAQ about fish pellet making machine

Puffing materials when the discharge tube does not discharge.

Reason: the configuration is too tight, adjusting the conical gap between the plug and the cone of the bullet is too small.

Method: Loosen the screw, tighten the adjusting screw plug back to 3-4 turns, and replace the air plug.

Inflation temperature can not meet the specified requirements.

Reason: The fish feed pelletizer wear-resistant sleeve configuration is not appropriate, wear parts are serious.

Method: Reconfigure the wear-resistant sleeve; replace the wearing parts.

Inflation temperature is not stable.

Reason: Material caking in the feed hopper, the feeding volume is unstable.

Method: Check the hopper and screw.

Suddenly no material after normal operation.

Reason: The discharge hole of the fish feed pelletizer is blocked by metal and other foreign objects.

Method: Stop the machine and clear the discharge hole.

Material back spray. Feeding too fast, too much in the fish feed pelletizer.

Reason: The material is not discharged smoothly and is blocked.

Method: Control the feed rate. According to the material processed readjust the extruded puffing parts.

Contact us

As you embark on your aquaculture journey, our Floating Fish Feed Extruder stands ready to be your trusted companion, propelling your business to new heights. With its exceptional buoyancy, efficient feed production, and remarkable adaptability, it emerges as a standout player in the fiercely competitive market.

Contact us now to unlock new potential in aquaculture! We look forward to providing tailored solutions to meet your ever-growing business needs. Click the inquiry button below to connect with our dedicated team and pave the way for a prosperous future.