Floating fish feed production line丨150kg/h fish feed mill plant

| Model | DGP65-B |

| Capacity | 150kg/h |

| Main power | 15kw |

| Cutter power | 0.4kw |

| Feed supply power | 0.4kw |

| Temperature control power | 1kw |

| Screw Diameter | 65mm |

| Size | 1750*700*1750mm |

| Weight | 600kg |

You can now ask our project managers for technical details

In today’s aquaculture landscape, the utilization of a floating fish feed production line has become an invaluable resource for numerous fish farmers venturing into the production of their own fish food pellets.

This shift aims to ensure a consistent and well-balanced quality of feed for their aquaculture operations. Our diverse range of fish food extruders offers various models, catering to different production needs, with output capacities ranging from 0.04-0.05t/h to 1.8-2.0t/h.

Within the spectrum of floating fish feed production lines, the 150 kg/h fish feed mill plant stands out as a smaller output option. Despite its size, this fish food pellet production line excels in continuous operation, showcasing high production efficiency.

The dry-type fish feed extruder production line presents a cohesive and integrated solution, comprising several machines seamlessly working together to meet the demands of modern fish food production.

Application scope of floating fish feed production line

Users: The floating fish feed production line is generally applicable to small, medium, and large fish food pellet machine manufacturers, fish farmers, etc.

Finished product: The floating fish feed production line can make fish feed, pet feed, cattle feed, poultry feed, etc. Customers only need to change different molds to realize making many different kinds of feeds.

Feeding objects: The final product can be fed to grass carp, catfish, tilapia, ornamental fish, turtles, pet dogs and cats, bullfrogs, and other animals.

How does the fish feed mill plant work?

The process of dry-type fish feed extruder production line

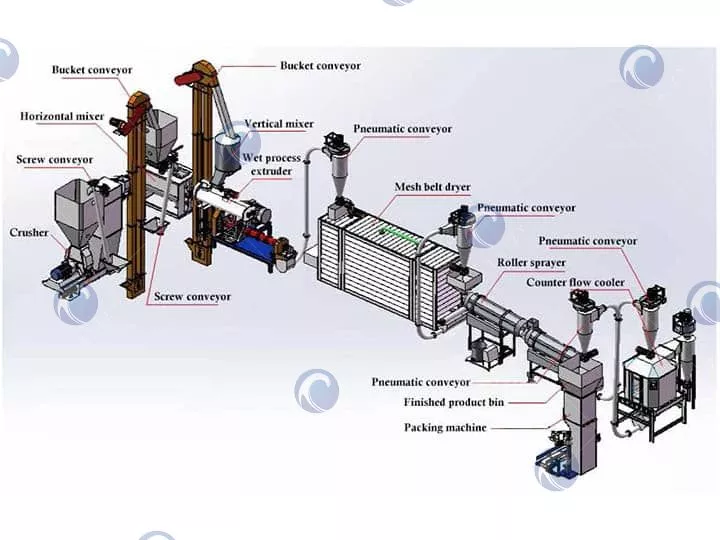

The process of floating fish feed production line includes raw material crushing → mixing machine → screw elevator → puffing machine → pneumatic conveying → drying machine → bucket elevator → counter-current cold cutting gas → oil spraying hanging machine → bucket elevator → finished product bin → packing machine.

Working process of floating fish feed production line

1. Raw Material Crushing with 9FQ Grinder:

The first step of making fish food pellets is that the raw material needs to be crushed. Since the raw materials are usually grains, we will equip 9FQ to process them. After treatment, the grains become powder.

2. Thorough Mixing with the Mixer:

The various cereal powders are meticulously mixed using a mixer, ensuring a homogeneous blend of ingredients.

3. Feeding to the Floating Fish Feed-Making Machine:

The stirred material enters the floating fish feed-making machine through the screw elevator. The fish food pellet mill works to process the raw materials into pellets.

4. Drying with Pneumatic Conveying Machine:

Then the pneumatic conveying machine sends these finished fish food pellet mill products to the dryer.

5. Cooling Process with Bucket Elevator:

The bucket elevator sends the dried fish food pellets to the inside of the cooling machine. Because the fish food pellets are extruded output by high temperature, the pellets need to be cooled.

6. Seasoning in the Seasoning Machine:

The cooled pellets will go into the seasoning machine. The seasoning machine will apply grease and seasonings to the fish food pellets. The seasoned fish food pellets are the finished fish food pellets.

7. Final Product Bagging with Packaging Machine:

Finally, we can bag the finished fish food pellets through the packaging machine. The bagged fish food pellets can be sold directly.

Parameters of 150kg/h fish food pellet production line machine

1. Hammer Mill

This machine is a professional grain crushing machine. Its internal structure is mainly hammer blades and screens. The machine can produce different fineness of powder by different sizes of holes in the screen.

| Power | 3kw |

| Capacity | 200kg/h |

| Size | 800*650*720 mm |

| Weight | 90kg |

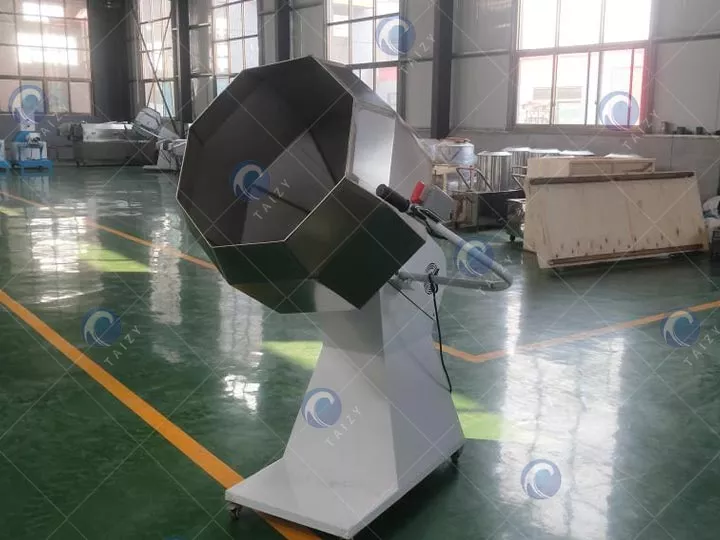

2. Mixer

The machine will mix different kinds of grain powder fully so that the nutrition can be distributed more evenly.

| Power | 3kw |

| Capacity | 200kg/h |

| Weight | 120kg |

| Material | stainless steel |

| Size(L*W*H) | 1430*600*1240mm |

3. Screw Feeder

This feeding machine is professional equipment for conveying powder. It has a rod-shaped screw inside, which can effectively convey the powder.

| Power | 1.5kw |

| Capacity | 300kg/h |

| Material | stainless steel |

| Size | 2400*700*700mm |

| Weight | 120kg |

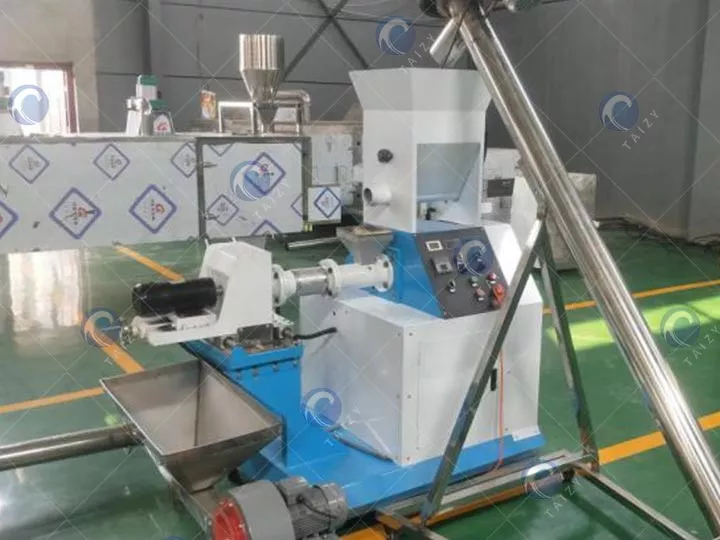

4. Fish Food Pellet Machine

This floating fish feed production machine will process the raw materials of fish food into various shapes of pellets. The processed pellets are usually cooked feed. We produce different models. Customers can choose the model according to their needs.

| Model | DGP65-B |

| Capacity | 150kg/h |

| Main power | 15kw |

| Cutter power | 0.4kw |

| Feed supply power | 0.4kw |

| Temperature control power | 1kw |

| Screw Diameter | 65mm |

| Size | 1750*700*1750mm |

| Weight | 600kg |

5. Fish Feed Dryer

This dryer adopts the form of mesh belt drying, and the upper and lower layers dry the fish feed pellets. After drying, the fish food pellets are drier and easier to store.

| Type | 3 layers 3m Length |

| Heating power | 18kw |

| Chain power | 0.55kw |

| Material | stainless steel |

| Temperature adjustment scope | 0-200℃ |

| Capacity | 180-200kg/h |

| Size | 3500*900*1680mm |

| Weight | 400kg |

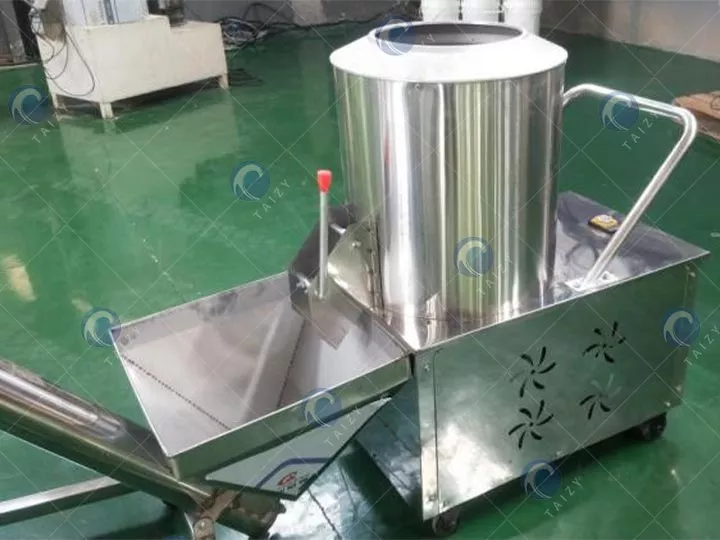

6. Seasoning Machine

This machine can spray grease and seasoning to the fish food pellet by the nozzle. At the same time, the machine rotates automatically, and because the machine is tilted, the seasoning can be fully attached to the fish food pellets.

| Power | 0.55kw |

| Capacity | 200kg/h |

| Material | stainless steel |

| Size | 1400*750*1650mm |

| Weight | 150kg |

Fish food pellet mill production line sold to Cote d’Ivoire

Our customer is from Côte d’Ivoire. He contacted us through our fish pellet mill website. Through our understanding, we know that the customer wants to open a floating fish feed production line. It was also the first time for him start such a business, so he wanted to buy a small capacity floating fish feed production line.

He wanted the machine to have a capacity of 100kg/h, so through our recommendation, the customer thought that a 150kg/h line would meet his needs. So we gave the PI to the customer and the customer felt good about these machines by browsing. He finally decided to place an order.

FAQ about floating fish feed production line

1. What determines the output of the fish food pellet production line?

According to the output of the fish pellet machine, we will match the customer with other machines of the right model.

2. Can I choose my own machine?

Of course, customers can choose any machine they want according to their needs.

3. Can the fish food pellet mill make other shapes of pellets?

Yes, you only need to change the mold of the material to be discharged.

4. Can you help us to calculate the plant area for the floating fish feed production line?

Of course, we have a professional team to help you calculate the corresponding plant area.

5. What if there is a problem during the installation and use?

We will provide you with online guidance to ensure that all the machines can be used normally by our customers. Our machines have a one-year warranty.