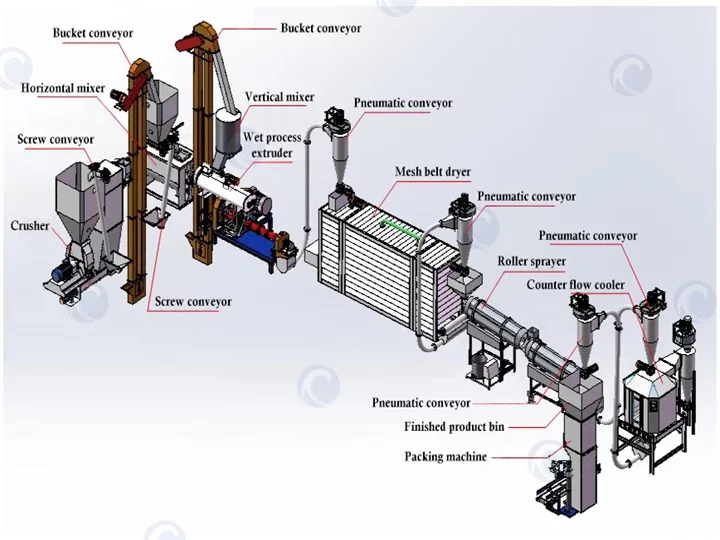

Composition of animal feed pellet production line

The animal feed pellet production line is a comprehensive system designed to process raw materials into uniform, compacted pellets suitable for consumption by livestock. Here’s an overview of the working principle of an animal feed pellet production line:

Contents

hide

1. Raw Material Crushing:

- The first step in the production line is to crush the raw materials to ensure they are suitable for further processing. The raw material crusher reduces the materials into appropriate particle sizes.

2. Mixing Machine:

- After crushing, various raw materials are uniformly mixed using the mixing machine. This ensures an even distribution of components in the feed to meet the nutritional needs of the animals.

3. Screw Conveyor:

- The screw conveyor plays a crucial role in transporting the mixed feed from the mixing machine to the next stage, which is the extruder. Its design allows for efficient and controlled transfer of materials.

4. Wet Process Extruder:

- In the extruder, a carefully controlled combination of high temperature and pressure is applied to the mixture. This process gelatinizes the starches and sterilizes the feed, rendering it highly digestible for the animals.

5. Pneumatic Conveyor:

- This system employs compressed air to convey the extruded pellets to the dryer. It ensures a smooth and efficient transfer process.

6. Mesh Belt Dryer:

- The dryer is responsible for reducing the moisture content of the pellets. Through precise temperature and airflow control, it optimizes the drying process, enhancing the stability and shelf-life of the feed.

7. Bucket Conveyor:

- This mechanical device facilitates the elevation of the dried pellets to the counterflow cooler. Its design ensures a controlled and reliable lifting process.

8. Counterflow Cooler:

- The counterflow cooler is a critical component for achieving the desired pellet size and texture. It uses high-speed cutting while simultaneously cooling the pellets with airflow to ensure an optimal final product.

9. Oil Spraying and Coating Machine:

- This machine applies a fine mist of lubricating oil or specific additives onto the surface of the pellets. This meticulous process enhances the taste and texture of the feed, making it more appealing to animals.

10. Bucket Elevator:

- Similar to the previous bucket elevator, this component assists in the elevation of the coated pellets to the finished product warehouse. It ensures a smooth transition between processing stages.

11. Finished Product Warehouse:

- The finished product warehouse serves as the final storage location for the processed animal feed pellets. This controlled environment ensures the quality and integrity of the final product until it is ready for packaging and distribution.

This meticulously designed production line guarantees a seamless and efficient process, resulting in high-quality animal feed pellets that meet the stringent standards of the industry.