Maize meal grinding machine | Grain grinder machine

| Model | 9FZ-280 |

| Capacity | 300-500kg/h |

| Size | 530*420*440mm |

| Weight | 60kg |

You can now ask our project managers for technical details

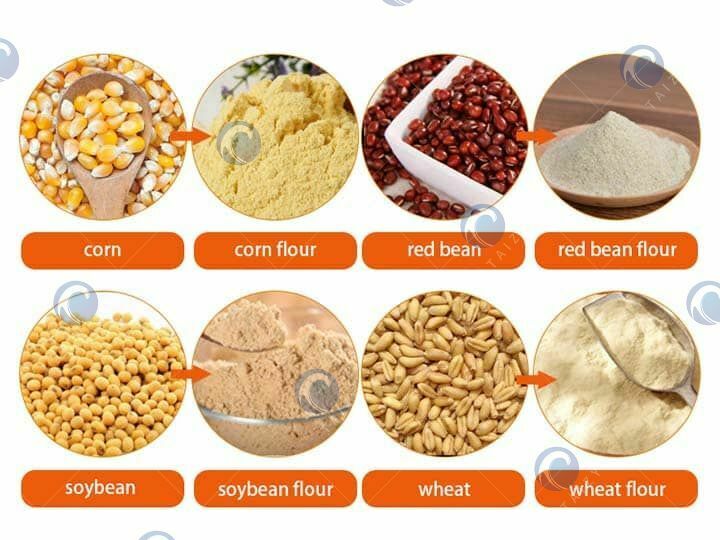

With the development of agricultural machinery, maize meal grinding machines are becoming more and more common. Many families now grow various grains, such as corn, wheat, soybeans, rice, etc. Some families need a small grain grinder in order to make their own grain powder.

We manufacture commercial grain grinders in many models and forms. For example, there are tooth claw crushers, grain crushers with cyclones, grinding refiners, etc. What’s more, we also have the hammer mill machine, which can grind grains and crush stalks.

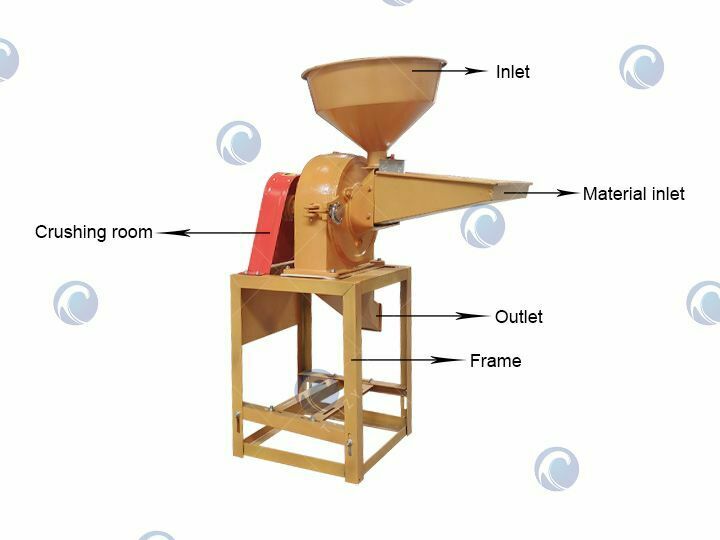

Type 1: Tooth claw crusher

The maize meal grinding machine has a wide range of processing. It can not only crush corn, wheat, beans, miscellaneous grains, and other grains and feeds. And it can also crush low-hardness minerals such as gypsum, powder, chemicals, clay, coal, etc.

The corn grinder machine is simple and easy to operate and is one of the necessary machines for household and commercial use. Regarding the fineness of the processed finished products, we have screens with different sizes of mesh. So, customers can choose according to their needs.

What raw materials can the maize meal grinding machine handle?

It can crush rice, dry (fresh) corn, wheat, dried (fresh) pepper, Chinese medicinal materials, whole grains, feed, etc. It is an ideal choice for household and commercial grinding.

What is the structure of the maize grinder machine?

The claw-type maize meal grinding machine mainly consists of six parts: the upper body, the machine cover, the rotor assembly, the screen, the feeding device, and the frame.

The machine body and the rotor form a crushing chamber together. The crushing of materials is completed in the crushing chamber.

How does the corn grinding machine work?

When the material enters the crushing chamber, it is quickly crushed into fine powder under the continuous impact of the round teeth and flat teeth. at the same time

Under the action of centrifugal force and airflow, it passes through the sieve hole and is discharged through the discharge port. The machine is simple in structure and easy to install, use and maintain.

What are the advantages of a tooth-claw home maize grinder?

- Wide application range. The grain grinder can process various materials, such as grains, miscellaneous grains, dried and fresh potatoes, low-hardness minerals, Chinese herbal medicines, etc.

- Small size and less floor space.

- The modified machine has a simple structure and is convenient to use and maintain.

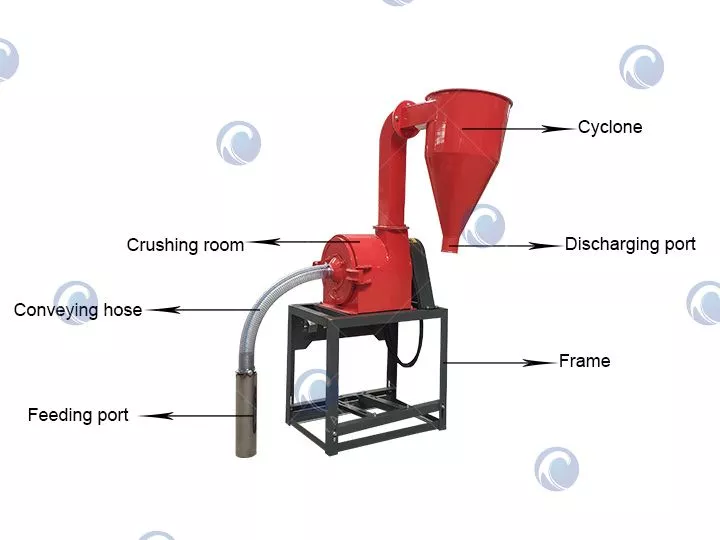

Type 2: Grain crusher with cyclone

The maize meal grinding machine with Cyclone is also a small household grain mill. It can also be used for seasoning by crushing Chinese prickly ash, chili, star anise, etc., in one machine with multiple functions. The mill has a grain suction tube and a cyclone.

The working of the machine is that the grain suction pipe will automatically suck the material into the crushing chamber. The cyclone will collect the dust that occurs when the machine is working, effectively preventing dust pollution.

What is the applicable field of grain mill machines?

Field: The multi-functional grain mill machine is widely used in food factories, dried vegetable stores, seasoning factories, and self-employed family farming.

Specific materials: Wheat, rice, millet, corn, soybeans, sesame, soybeans, sorghum, highland barley, and other grains, as well as other chemical raw materials. The thickness of material processing can also be adjusted.

How does the corn crusher work?

Grain grinder machine’s structure

The structure of this maize meal grinding machine is basically the same as that of Type 1. It consists of a feeding, conical mill, and separation system, except that it has one more self-suction pipe and one cyclone than Type 1.

The machine has a simple structure, sound processing, and installation technology, and is a pulverizer with excellent performance.

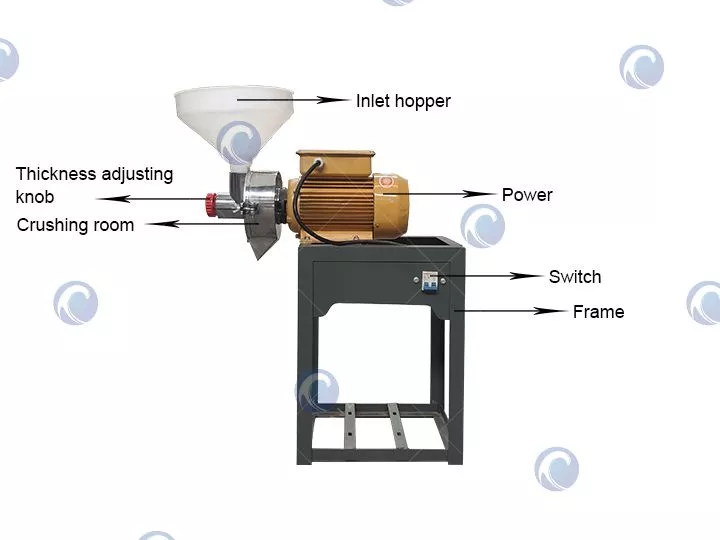

Type 3: Grain grinding and pulping machine

The maize meal grinding machine is wet grinding equipment. The crushing part of the machine is made of stainless steel. It can be used for the wet grinding of grain materials such as rice, soybeans, corn, and potatoes.

Since the material part of the machine is made of stainless steel, the final product can be eaten directly.

The people who are suitable for the grinding and refining machine

This maize meal grinding machine is suitable for bean products factories, catering services, canteens, restaurants, and individual businesses. As for the application materials, it is biased toward all kinds of food, medicine, and so on.

How does the grain grinder work?

Working principle of grain mill machine with cyclone

When the pre-treated materials such as cleaning and soaking enter the mill from the hopper. They enter between the relatively moving upper and lower sand discs under the action of centrifugal force. The mutual impact and extrusion of materials and the shearing.

The comprehensive action of rubbing and tearing makes the material grind from the inside to the outside, from coarse to fine along the plane of the sand disc.

What is the structure of the grain crusher for corn and wheat?

The main components of the maize meal grinding machine are a feed hopper, fineness adjustment button, crushing chamber, power, switch, frame, etc.

What are the highlights of the high-quality grain grinder?

- If it is used for grinding powder, the grinding fineness can reach 80-100 mesh.

- The unique material door mechanism and grinding chamber effectively solve the problem of water leakage of the equipment.

- The well-designed grinding chamber can make the slurry flow smoothly, with less material accumulation and easy cleaning.

- Edible sand tablets with a special formula, high output.

- Clean and hygienic, the whole working channel from feeding, and grinding to discharging is made of stainless steel.

Grain crusher machines – Taizy Your Best Choice

- We are a professional manufacturer of agricultural machinery. The design, structure, and shape of the machine are all in line with the needs of the public.

- The manufacturing maize meal grinding machine adopts high-quality material. The whole production process is strictly supervised, and the manufactured machines are of high quality and high standard.

- We have professional sales staff to provide customers with professional machine solutions.

- After the customer purchases the machine, we will update the logistics status to the customer in real-time, so that the customer can rest assured.

Small grain grinder machine sold to Sweden

Our customer from Sweden bought a soybean peeling machine and a small grain grinder from us. After communicating with the customer, I learned that the customer wants to make soybean flour by himself for sale. Since soybean ingredients need to be dehulled, the customer needs a maize meal grinding machine.

After understanding the customer’s needs, we provided the customer with pictures, videos, and parameters of the maize meal grinding machine. Finally, the customer chose the Type 1 maize meal grinding machine. After the customer pays, we immediately arrange the packing and shipping machine for the customer.