Pet food production line丨Pet food extruder processing line

| Machine name | Double Screw Extruder |

| Output | 120-180kg/h |

| Feeder power | 0.75kw,frequency control |

| Extruding power | 22kw, frequency controlcutting |

| Power | 0.75kw,frequency control |

| Oil pump power | 0.37kw |

| Heating power | 10kw, three areas controlled separately |

| Speed control | Three frequency control speed |

| Dimension | 2700×1500×1800mm |

You can now ask our project managers for technical details

Pet food production line is professional equipment that can produce various shapes of pet food. The line generally has several machines combined with a high degree of automation. And different models can produce different outputs. Customers can choose the right machine model according to their needs.

Besides, we have different discharge molds, so we can produce many different shapes. There are many machines included in our production line, so customers can buy the whole set or choose the equipment they need.

Using scopes of pet food production line

1. Raw materials:

Starch raw materials: corn protein powder, corn flakes, gluten, wheat bran, or malt type.

Protein raw materials: soybean meal and soybean coarse meal, meat meal bone meal, poultry meal, and fish meal.

2. Applicable pets:

Dog, Cat, Fish, Bird Food, etc.

3. Users:

Professional pet food producers.

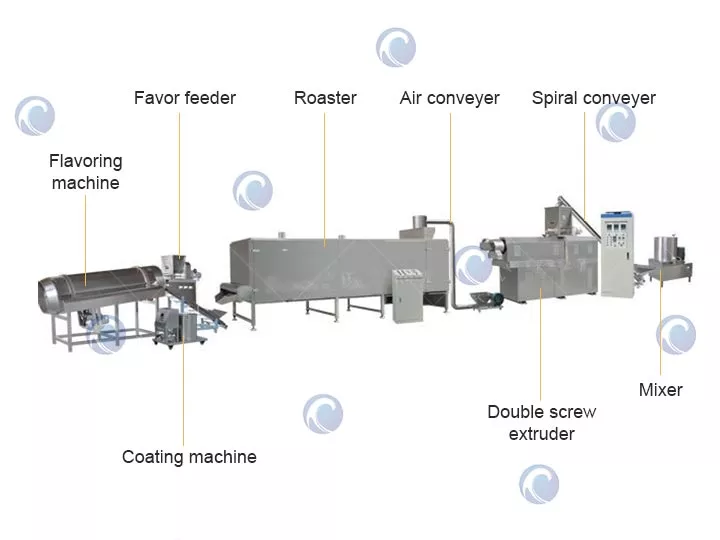

Main components of the pet food extruder processing line

Nowadays, more and more people are feeding their pets. Therefore, the demand for pet food is also increasing. At the same time, people’s needs for the nutrition and quality of pet food are getting higher and higher.

Therefore, the use of professional and high-quality pet food production equipment is also the demand of manufacturers.

Our pet food extruder processing line includes a flour mixer, spiral conveyor, twin screw extruder, air conveyor, continuous dryer-electricity type, conveyor, flavoring machine, oil spray machine, condiment adder, cooling machine, packing machine, etc.

Workflow of dry pet food production

Process flow: raw material composition → mixing → conveying → extrusion and puffing → conveying → drying → oil spraying → flavoring → packing. In this process, each step is handled by professional equipment.

Main equipment and functions of the animal food processing line

1. Mixer

This flour mixer is used to mix raw materials such as corn flour, and rice flour with liquid and other additives. It is the second step in the pet food production line.

| Power | 4KW |

| Mixing time | 90-120 seconds per time |

| Tank volume | 30kg/time |

| Dimension | 1100 x 1050 x 1400mm |

| Voltage | 380V 50HZ Three Phase, or according to buyer’voltage |

2. Spiral Conveyer

The machine can convey the mixed material inside the pet grain extruder.

| Power: | 0.75KW |

| Dimension | 3100 x 800 x 2000mm |

| Voltage | 380V 50HZ Three Phase |

3. Double Screw Extruder

This machine is used for continuous automatic pasting of flour and starch.

After dosing, the material is worked by two co-rotating screws composed of segmented modules with the following functions: forward and backward conveying, mixing, adding additives, injecting liquids, degassing, cooking, and forming.

It is the machine that produces the pet food in the pet food production line.

| Output | 120-180kg/h |

| Feeder power | 0.75kw,frequency control |

| Extruding power | 22kw, frequency controlcutting |

| Power | 0.75kw,frequency control |

| Oil pump power | 0.37kw |

| Heating power | 10kw, three areas controlled separately |

| Speed control | Three frequency control speed |

| Dimension | 2700×1500×1800mm |

4. Air conveyor

| Power | 0.75KW |

| Dimension | 2900 x 160 x 2300mm |

| Voltage | 380V 50HZ Three Phase |

5. Continuous Dryer-electricity type

This dryer in the pet food production line is used to roast the extruded snack, make it more crispy, and dry the product to reduce the moisture percentage, so that the snack could get a long time shelf time and better taste.

| Heating type | electric heating(if need gas or diesel or steam heating type, tell us in advance) |

| Motor power | 1.1KWelectricity type, Electric heating power:54kwIf gas type, gas consumption:10-12m³/hIf diesel type, diesel consumption:6-8kg/h |

| Layer | three layers |

| Dimension | 5000 x 1100 x 1800mm |

| Voltage | 380V 50HZ Three Phase |

6. Flavoring machine-single drum

The flavoring machine mixes the seasoning and oil and snack in the rotating drum.

| Hoister Power | 0.55KW |

| Feeder hopper power | 0.37kw |

| Rotating drum power | 0.75kw |

| Dimension | 3500 x 1100 x 1700mm |

| Voltage | 380V 50HZ Three Phase |

7. Oil Spray Machine

This machine is combined with the flavoring machine, the pump sprays the oil on the surface of the snack.

| Pump Power | 0.75KW |

| Electric heating power | 3kw |

| Tank volume | 50L |

| Dimension | 1200 x 1100 x 1300mm |

| Voltage | 380V 50HZ Three Phase |

8. Condiment adder

It is used for adding powder on the surface of the product, screw feeding, and manual speed can be adjusted

| Power supply voltage | 380V/50HZ |

| Installed power | 0.37KW |

| Hopper volume | 10kg |

| Production capacity | 100-200Kg/h |

| Size | 0.7×0.4×0.4m |

9. Cooling machine

Used for first cooling and conveying of products

| Power supply voltage | 380V/50HZ |

| Installed power | 0.75KW |

| Fan | 4 0.15kw/pc |

| Production capacity | 100-300Kg/h |

| Size | 5.0×0.4×0.4m |

Successful case

The pet food production line is sold to Italy. Some time ago, a customer sent us an inquiry for a pet grain production line of 150kg-250kg/h.

We contacted the customer immediately. Through our communication, we understood that the customer was interested in the pet food production industry and wanted to purchase the corresponding machines for his business. The customer looked at our quotation and decided on a few machines that he needed.

Our sales manager then recreated the quotation for the customer. After reading it, the customer said he would place an order next week. The customer then paid and we arranged for the pet food production line to be shipped directly to Italy.

FAQs of Shuliy’s pet food production line

1. What is the price of the pet food production line?

Our pet food production line contains several machines, so customers can buy all of them or select the ones they need.

Therefore, the price of the machines varies depending on the combination of machines.

We will recommend the right combination of machines for our customers.

2. What is the material of the machine?

As the machine is making food, our machines are made of stainless steel and can directly contact the food material of the machine. Customers can place orders with confidence.

3. What is the output of the pet food production line?

We have commonly sold 150KG/H and 250KG/H output.

4. Can the machine produce different shapes of pet food?

Yes, you only need to change the shape of the discharge mold you need.

5. Can you provide the floor space and layout of the pet food production line?

Yes, you can. We will provide the corresponding floor space and layout plan if you need it.