Fish pellet making machine | Floating fish feed making machine

| Model | DGP40 |

| Capacity (t/h) | 0.04-0.05 |

| Main power (kW) | 5.5-7.5 |

| Feeding power (kW) | 0.4 |

| Spiral diameter (mm) | Φ40 |

| Cutting power (kW) | 0.4 |

You can now ask our project managers for technical details

The fish pellet making machine can process the material directly into feed pellets. The finished products after processing can be floating or sinking and can be in various shapes. And these pellets are cooked, which is good for fish to digest and absorb.

Now there are many fish farmers who own several fish ponds. Then they can choose to use the fish food pellet machine to make fish food by themselves. Making it by yourself is good for the nutrition and hygiene of fish food, and saves the expense of buying fish food.

What is a fish pellet-making machine?

A fish pellet-making machine is a device that can process various grain powders into mature fish food pellets. These raw materials can be soybean meal, corn, peanut meal, cotton meal, rice bran, bran, and so on. And we should put a proportion of water into these power materials.

The feed can be mixed with a mixer or directly processed with a vertical feed crusher. Then we can put the processed feed directly into the fish food-making machine.

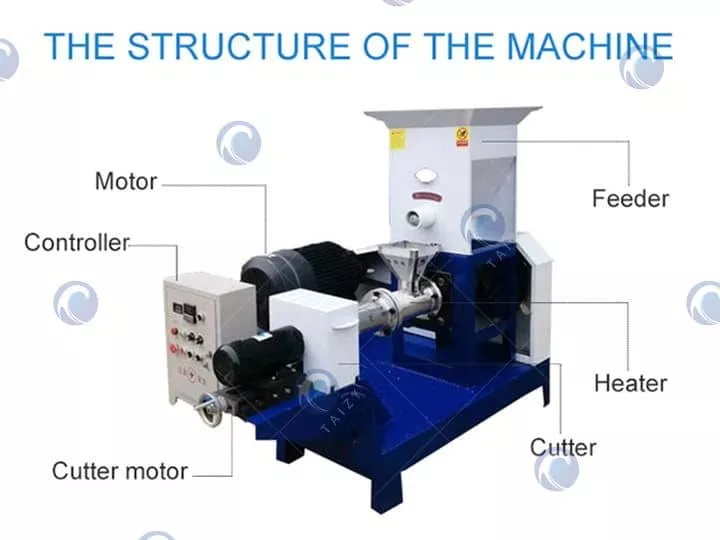

The power of the fish pellet-making machine can be an electric motor and diesel engine, which can meet the demand of different customers for power. The floating fish feed machine has a simple structure, easy operation, and high working efficiency, which is the preferred equipment for fish farmers.

Features of the floating fish feed-making machine

- The fish food machine has high working efficiency, from putting in the material to the finished product, it only takes a few seconds.

- Our floating fish feed-making machine can produce different shapes of pellets through different molds. Customers can choose molds according to their needs.

- The fish pellet making machine models are complete from 400KG per hour to 2 tons per hour, we have different models to meet the needs of customers.

- The electric heating device is used to improve the expansion rate and floating time of the feed.

Raw materials scope of the fish food-making machine

Generally speaking, the raw material of fish pellet making machines contains corn meal, wheat meal, rice meal, soybean meal, vegetable meal, soybean meal, cotton meal, peanut meal, bran, grass meal, and so on.

In addition, we can add fish meal, shrimp meal, crab meal, and other animal protein to the fish food. These two nutrients together can increase the nutrition of fish food pellets.

How does the small fish feed pellet machine work?

We put the raw material into the fish pellet making machine. Then the extrusion screw pushes the raw material from the feed box to the compression chamber and gets preliminary extrusion and heating.

After that, the material will be extruded and heated up continuously to different degrees. Finally, the extruded material will come out through the die.

Working video of extruder machine for fish feed

Detailed technical of floating fish food machine

| Model | DGP40 |

| Capacity (t/h) | 0.04-0.05 |

| Main power (kW) | 5.5-7.5 |

| Feeding power (kW) | 0.4 |

| Spiral diameter (mm) | Φ40 |

| Cutting power (kW) | 0.4 |

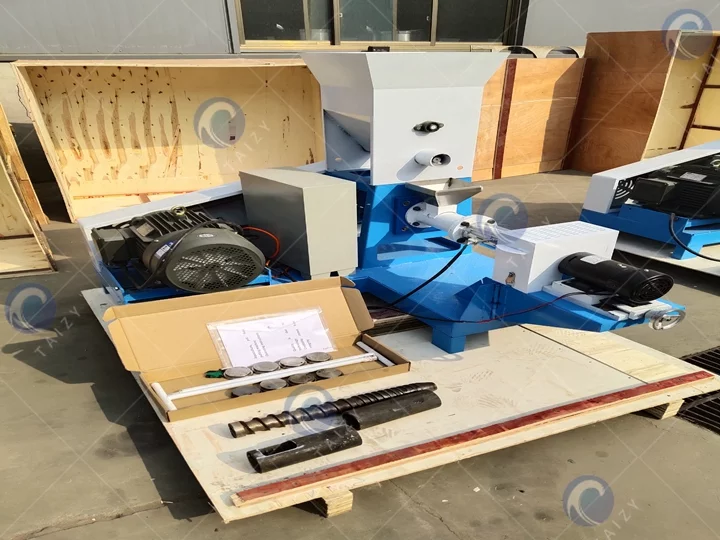

Main structure of the fish feed extruder machine

Fish pellet making machines mainly include a feeder, extrusion, and expansion device, power and transmission system, frame, electric control system, and so on. The whole machine has a compact and simple structure. And there is an independent electric control cabinet, which is easy to operate.

Invest in our fish pellet making machine

Invest in our fish pellet making machine for efficient and high-quality fish feed production. With advanced features and easy operation, our machine will elevate your aquaculture operation to new levels of success.