Fish feed pellet mill with good price to Rwanda

A customer in Rwanda, managing a growing aquaculture farm, recently approached us in search of a solution to their feed production challenges.

They needed a fish feed pellet mill capable of producing high-quality floating and sinking feed to meet the diverse dietary needs of their fish stock.

The client aimed to reduce feed costs and enhance production efficiency as their aquaculture operations expanded.

Challenges identified

The customer outlined several requirements and challenges, including:

- Versatility in pellet type. The ability to produce both floating and sinking pellets for different fish species.

- Raw material processing. Efficient handling of varied raw materials such as animal innards, maize, fish powder, and wheat chaff.

- Cost efficiency. A durable, high-performance machine that minimizes operational expenses.

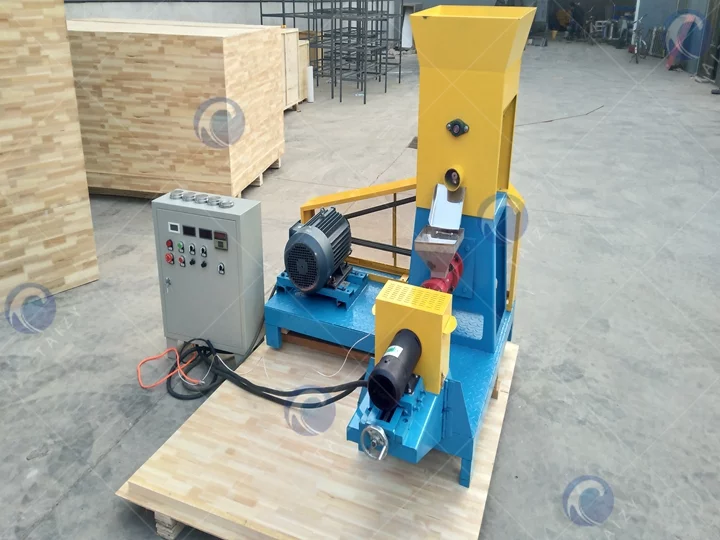

Solution: The DGP70-B fish feed pellet mill

After evaluating the client’s needs, we recommended the DGP70-B Fish Feed Pellet Mill, known for its robust design, efficiency, and adaptability.

Key features of the DGP70-B

- Higher capacity. With its larger screw diameter, it processes greater quantities of raw materials efficiently.

- Versatile integration. Combines seamlessly with complementary equipment like grinders and mixers, enabling streamlined feed production.

- Raw material flexibility. Capable of processing materials such as innards, bone powder, fish powder, cotton seeds, maize, wheat chaff, and rice dust. This allows customized feed formulations to meet specific nutritional needs.

- Advanced extrusion technology. Produces uniform, highly digestible pellets, ensuring optimal nutrient absorption.

Raw material and nutritional benefits

The DGP70-B excels in processing a wide range of raw materials, including:

- Animal innards & bone powder. Rich in protein and minerals for robust fish growth.

- Fish powder. Provides essential fats and proteins.

- Grain-based materials. Cotton seeds, maize, and rice dust contribute carbohydrates and fiber, creating a balanced feed.

Implementation and training

Our technical team facilitated the installation of the fish feed pellet mill in Rwanda, providing:

- Machine setup. Proper calibration to ensure efficient operation.

- Training. Guidance on using grinders and mixers alongside the mill for seamless production.

- Maintenance tips. Instructions on routine care to maximize machine lifespan.

Results and benefits

The customer has experienced remarkable improvements in their operations:

- Efficient production. Daily production targets are now easily met with high-quality feed pellets.

- Cost reduction. On-site feed production has significantly lowered feed costs.

- Enhanced fish health. Nutritionally optimized feed improved fish growth rates and overall health.

- Sustainability. The ability to use locally available raw materials reduced reliance on imported feed.

Conclusion

The successful implementation of the DGP70-B Fish Feed Pellet Mill in Rwanda highlights its versatility and efficiency in aquaculture feed production. By addressing the unique challenges faced by the client, we delivered a comprehensive solution that supports their expanding business.

If you’re looking for a high-performance fish feed pellet mill, the DGP70-B offers an unparalleled combination of capacity, customization, and cost-effectiveness. Reach out to us to learn how it can transform your aquaculture operations!